NatureScot Research Report 1312 - Review of the minimum bullet weight for the lawful culling of all deer species in Scotland

Year of publication: 2022

Authors: William Lamont, James Govan, Professor Jimmy Simpson and Callum Fergusson

Cite as: Lamont, W., Govan, J., Simpson, J. and Fergusson, C. 2022. Review of the minimum bullet weight for the lawful culling of all deer species in Scotland. NatureScot Research Report 1312.

Keywords

non-lead; copper; ballistic gelatine; ballistic soap; .243w, The Deer (firearms etc) (Scotland) Order 1985

Background

The current criteria as laid out by Deer (Firearms etc) (Scotland) Order 1985.

This prescribes that it shall be lawful to use a rifle which is capable of firing the following lawful ammunition: -

- For shooting deer of any species, a bullet of an expanding type designed to deform in a predictable manner of not less than 100 grains (6.48 grams) with a muzzle velocity of not less than 2,450 feet per second (746.76 metres per second) and a muzzle energy of not less than 1,750 foot pounds (2,373 joules).

The use of lead ammunition, in rifles to kill wildlife will be phased out either through voluntary or legislative means. The timescale for this is likely to be within the next five years. This has prompted a review of current minimum criteria and of particular focus is the suitability of bullet / ammunition combinations for culling all species of deer with a bullet weight of less than 100gr. This is linked with the common application of the use of .243 calibre in Scotland and the limited availability / suitability based on rifle bore twist rates of non- lead ammunition in 100gr and above.

Main findings

- Copper bullets retain most of their weight when passing through the thoracic cavity of a deer, therefore are more likely to exit the carcass.

- Copper bullets produce a cleaner carcass in the larder, due mainly to the lack of lead fragments. These fragments cause numerous small wound tracks which create more tissue damage and bruising.

- Despite considerable effort, only seven factory types of non lead .243w ammunition were able to be sourced in Scotland for this project. None of which were 100 gr, the minimum deer legal bullet weight for larger deer species in Scotland.

- Copper bullets for reloading the .243w are available in a range of weights of 90gr plus. Notably produced by Nosler, Hornady, Lapua and Barnes. This allows reloaders to potentially come very close to replicating a non lead.243w cartridge that would meet existing legal requirements.

- With the exception of bullet weight, six out of seven of the non lead .243w cartridges produced a performance that would fit with current legislation contained in paragraph 3a of The Deer (firearms etc) (Scotland) Order 1985.

- Consideration could be given to amending The Deer (Firearms etc.) (Scotland) Order 1985 with an addition of a minimum calibre stipulation of .240 along with a reduction in bullet weight from 100gr to 80gr for the culling of all species of deer.

Acknowledgments

The group is grateful for the support and facilities made available by Rory Richardson, manager at Creag Meagaidh National Nature Reserve. Without which the fieldwork carried out for this report would not have been possible.

Abbreviations

.243 Winchester – .243w

Grain(s) – gr

Foot/pounds – Ft/lb

Feet per second – Fps

Gilded metal eXpanding – GMX

Expansion Tip – E-Tip

Introduction

In order to promote and encourage the phase out of non-lead ammunition NatureScot needs to promote Best Practice using the most relevant and contemporary information. An initial study undertook the following which provides some further context to this project.

- A catalogue of the non-lead ammunition currently available (or likely to be available within 3 years) that would be suitable to kill the range of wildlife currently controlled (either as quarry species or under licence) in Scotland.

- Consideration of the likely effectiveness of the alternatives identified using the information provided by manufactures and other reliable sources.

- To identify any issues arising from using non-lead in relation to the current rifle/ammunition combination required to be used to control different species of deer in Scotland.

The scope of this project was to consider:

- What would be the impact of reducing the minimum bullet weight (of both lead / non lead bullets) for all species to 80-85 grains.

- Undertake testing to review terminal ballistic performance with consideration for killing efficacy and deer welfare through study of wound profiles.

- The production of material by way of a report and imagery that could be used for the production of Best Practice Guidance.

Assumption to undertake range testing of rifle / ammunition combinations to understand relationships between velocity, muzzle energy, bullet weight and construction linked with downrange performance. This could include commercially available cartridges along with hand loaded combinations of currently available bullet heads.

Context

The Scottish deer population comprises Red, Roe, Fallow and Sika. The average recorded Scottish deer cull based on returns over the majority of the last 25 years has exceeded 100,000 per annum. The red deer component is in excess of 50%. It is believed that in addition to the reported cull, unreported culling in recent years could increase the overall cull figure to ~ 180,000.

Current firearms regulations have been enshrined into ‘Best Practice Guidance’ which is now considered the deer industry leading standard in Scotland from which deer managers aim to work. The regulations require bullets for culling deer to be “expanding” ammunition. This means the bullet must be capable of deforming and so releasing its energy in a predicable progressive manner to cause maximum vital tissue damage which results in a rapid loss of blood, unconsciousness and death in a short time period.

Most commonly used calibres of rifle used in deer management are capable of meeting the legal regulations for the culling of all deer species in Scotland. To meet current legal parameters the larger species of deer in Scotland will be culled using rifle calibres in excess of .243w usually .270 Winchester, .308 Winchester and similar. However, the .243w calibre rifle is also capable of meeting the present legal requirements for shooting our largest species of deer and remains a popular choice. An indication of the popularity of the .243w can be found on the gun sales internet site Gun trader. Recently of 211 rifles for sale in (larger deer legal calibres) excluding .22 centrefire for Roe deer only, 87 or 41% were chambered in the .243w cartridge.

In practical terms the .243w cartridge is the smallest mainstream calibre that can currently comply with minimum velocity, muzzle energy and bullet weight legislation). However, going forward with non-lead ammunition and given the lack of commercially available 100gr non-lead cartridges, bullet choice for the culling of larger deer is constrained by paragraph 3a of The Deer (firearms etc) (Scotland) Order 1985, which requires bullets of a minimum of 100gr to be used.

This report considers whether the 1985 order can be changed by the lowering of the 100gr minimum requirement, and hence allowing the use of sub 100gr bullets in the .243w cartridge to achieve the safe and humane culling of Scotland’s larger deer species.

Both deer managers and industry Wild Deer Best Practice Guidance (WDBPG) in Scotland are comfortable with the present regulations employing a combination of rifles and ammunition as described above.

Copper is a less toxic metal than lead. Unlike lead core bullets which require a complicated manufacture, non-lead copper bullets can be manufactured on a computer-controlled lathe on a small-scale operation. Some of the copper bullets from large manufacturers require considerable manufacturing skill. These are the ones which are manufactured in such a way that they deform into petals or fragment in a predictable manner. The simple copper bullets produced on a lathe may have nothing more than a hole drilled in the point. The dimensions of this cavity may be estimated or they may be carefully calculated by testing. Such bullets are aimed at the home loaders of ammunition, with little efficiency testing.

Bullets from different manufacturers vary in their effectiveness to kill deer. Lead bullets have been around more than a century (and in ball form considerably longer) whilst non-lead ammunition is still mostly in the developmental phase. Although the non-lead bullet types and deer legal cartridges can in some cases provide a reasonably varied selection, this is limited in the case of the .243w cartridge.

Expanding bullets are almost without exception constructed from a combination of lead and copper metals. The basic lead bullet construction relies on a thin copper outer case with a lead core. The weight of the bullet varies depending on the size of the deer to be culled. Heavier bullets for larger species of deer such as red deer and lighter bullets for the smaller species, such as roe deer. However, the technology of bullet design has significantly improved since the 1980’s with manufacturers developing new methods of ensuring that expanding ammunition can be relied upon to work consistently and predictably to humanely cull deer.

The tip of the bullet has traditionally been what is called “soft nose” where lead core protrudes from the copper casing, some more modern designs have a hollow point or a polymer tip. These bullet tip designs are intended to ensure that the bullets start to deform or expand as the bullet enters the deer thorax. This expansion effect exposes the soft lead core and so ensures the release of large amount of energy resulting in rapid fatal tissue damage. In addition to the advances in bullet design, advances in gun powder development, overall firearm technology and design, ensure bullets are very accurate and can travel at high velocities.

The larger calibres of rifles, as described above present no major issue with meeting the present legislation even using non-lead cartridges. However, some changes may be needed in the weight of bullet used by deer managers to ensure adequate velocities to be achieved and to ensure good expansion of copper bullets.

This project considered the .243w calibre with regard to its efficiency and humane use for culling larger deer species using commercially available factory loaded cartridges with non-lead bullets in the weight range 80-100gr.

This report contains the outcome of scientific trial using recognised methodologies namely; chronograph studies, test firing into ballistic soap and ballistic gel, bullet retrieval, assessment of wound profiles and evaluation.

Methodology

Range testing was undertaken with a Sako 75 .243w rifle with a barrel length of 21 ¾ inches, 1 in 10 barrel twist rate, fitted with a Lawrence Precision Nexus titanium moderator and a Swarovski 8x 56 telescopic sight.

The purpose was understand the relationships between velocity, muzzle energy, bullet weight and construction linked with terminal performance. using commercially available factory loaded cartridges. The group did not investigate customised rifles or hand loaded non-commercial ammunition specially designed to increase the bullet weight and velocity and muzzle energy of the .243w cartridge.

The group sourced relevant factory ammunition from suppliers across the UK. One which could not be sourced (90gr Winchester/Nosler e-tip) because it was out of stock was replicated by Precision Rifle Services to factory specifications. Seven types of non-lead cartridges were obtained and tested. Three types of lead core commercially available .243w factory cartridges were used for comparison.

Ballistic soap and ballistic gelatine were used to assess terminal ballistic performance which allowed an understanding of the process of how a bullet interacts with simulated animal anatomy and its subsequent performance. The reason these materials are “ballistic” is that they are calibrated to a similar consistency as animal tissue.

Materials

The ballistic soap was sourced from John Drury & Co Ltd and M Bedforth & Sons, 28 River Street, Brighouse, West Yorkshire, HD6 1NJ. Their clear melt and pour soap were supplied in 30 litre buckets. The soap was calibrated to approximately the Federal Bureau of Investigation (FBI) standard using a steel BB pellet at 590 Fps. As comparisons are critical to the project, standardisation of the soap used was more important than adhering to an absolute standard. All soap used was from the same batch. The size of the soap block was of sufficient size that there was no distortion to the outer margins of the soap block when shot. If bullet placement is not in the middle of the block, then the block must be discarded and another shot taken to ensure bullet placement in the centre of the block.

Dentstone KD yellow dental stone cement was used to mould the cavity in the soap created by the bullets. The dental stone cement mould produced by casting the cavity in soap is directly comparable with the wound profile created in an animal. The cast, or wound profile was retained as a permanent record, its volume can be measured and scale photographs compared by overlaying them on scaled images of deer anatomy.

The ballistic gelatine used help visualise terminal bullet performance, was Ballistic 3 gelatine, sourced from Gelita UK Ltd. Their standardised procedure for casting blocks was adhered to during the preparation.

Testing process

- All shots were fired at 100 metres at an open-air range. The targets being 30 kg tubs of soap or 30 kg blocks of gelatine. The procedure was to fire three shots at a paper target to confirm each cartridge zero and then one shot at the centre of each of the soaps and gelatine blocks to record performance.

- Tests were undertaken over 2 consecutive days under similar climatic conditions. This ensured ensure consistency of assessment of each cartridge so that ambient temperature, temperature of soap and ballistic gel and range to target were comparable.

- All seven of the .243w cartridges loaded with copper bullets and three weights of lead core bullets were fired into the ballistic gel blocks. Bullets were recovered in a custom-made bullet catcher if they exited the soap or gelatine. A sheet of soft rubber ballistic linotex was placed to cover the gap between the soap/gelatine and the catcher. All but one bullet was caught in the first rubber sheet, or on the ground in front of the catcher. The bullet from sample 4 remained in the gelatine 4 cm from the end.

- All the .243w cartridge muzzle velocities were measured with a Magneto Speed barrel mounted chronograph. This unit is designed to be fitted to the barrel and has the facility to record a three-shot average muzzle velocity.

- For casting wound profiles, the soap was marked with tacks corresponding to the reference number of the cartridge being tested immediately after shooting. When the wound profile in each soap block was cast with dental stone cement, the cast was permanently etched with the cartridge reference number. The stone cast was then released from the soap block by cutting away the soap.

- The volume of the wound profiles plaster cast was then measured by water displacement, recorded and photographed to scale along with the lead ammunition for comparison.

Method of assessing bullet impact on red deer thoracic sections

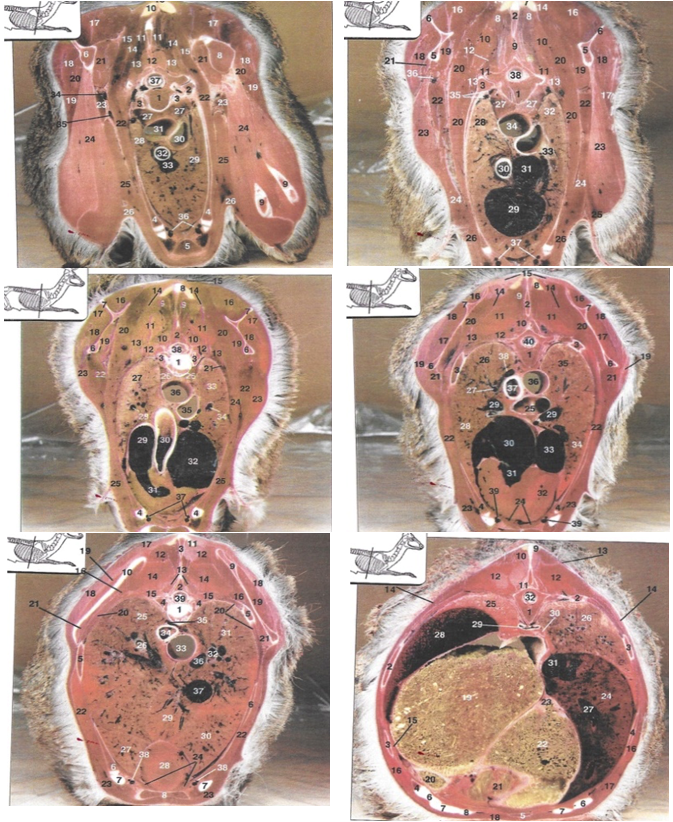

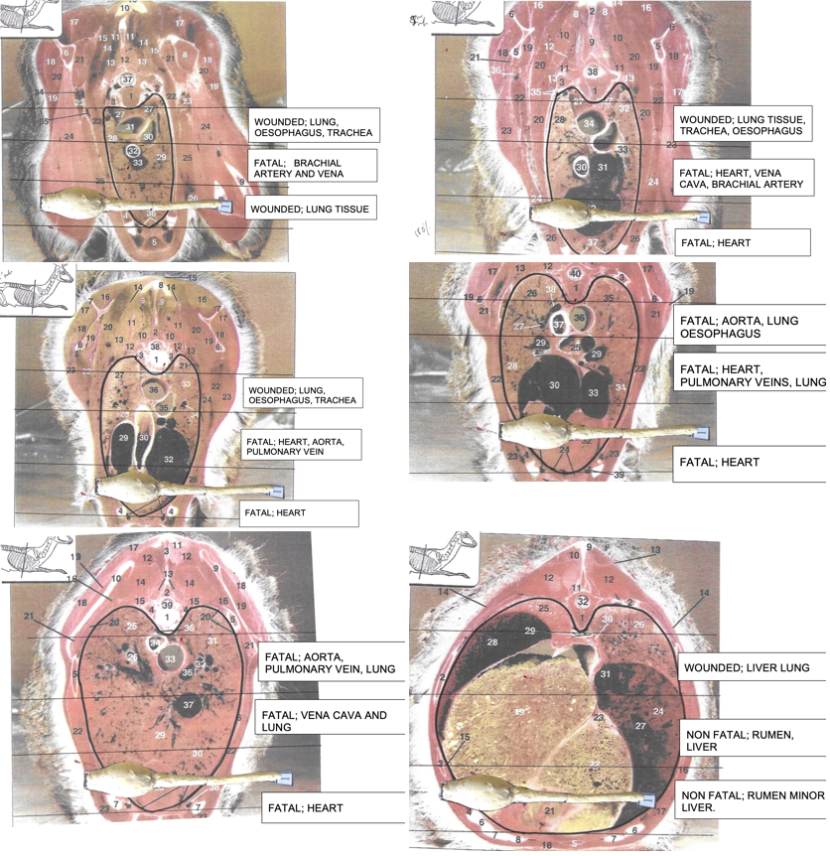

A sample using CT and MRI scanning of the red deer thorax was published by Horn (1998). This has led to the production of a series of anatomical cross sections of the organs and tissues present at each rib space throughout the thoracic cavity.

In order to assess the effectiveness of the .243w using copper bullets on thoracic tissues, each rib space was divided into three sections as shown by the horizontal black lines as shown in figure 1.

A cross-section diagram of a red deer thorax with black lines showing divisions across the thorax to represent the three outcomes below:

One of three outcomes was recorded for each bullet at each rib space and within the three sections at each rib space.

- Fatal. Rapidly fatal outcome.

- Wounded. May have a fatal outcome but wounding is also possible.

- Non-fatal. Non-fatal outcome causing wounding and deer moving away.

Permission has been given to use this data for the purposes of studies into the humane culling of red deer. Images of the cross-sectional rib slices from Horn’s publication are shown in sequence below. The numbers on each slice are codes for the different internal organs and blood vessels present.

WDBPG dictates that shots should be placed between rib space 3 and 9 to ensure a fatal outcome. The actual content within each rib space is highlighted in thick black ink (figure 1). Tissues outside this black line represent the muscles, skin and hair of the thoracic wall at each rib space.

Results

Comparison of non-lead cartridges with lead equivalents

Seven commercially available .243w non-lead cartridges were evaluated and results were compared with three .243w lead based cartridges. The factory values quoted for velocity and muzzle energy were compared with actual values tested using the Sako test rifle. Factory data is usually based on measurements recorded in a longer barrel length of typically 24 inches, rather than the 21 ¾ inch barrel on the test rifle. Greater barrel twist rates can give higher velocity values than would typically be seen in a standard hunting rifle.

In addition, the residual weight of bullets was recorded after they had been fired through ballistic gel to assess bullet weight retention. The data for these values is shown in the table 1 below.

Muzzle energy generated by each cartridge in the test rifle was calculated using the Quick Load ballistic programme using the recorded muzzle velocity and corresponding bullet weights.

Table 1

|

Sample No |

Metal |

Make |

Weight Gr |

Measured Fps |

Factory Fps |

Measured Ft/lb |

Factory Ft/lb |

|---|---|---|---|---|---|---|---|

|

1 |

Copper |

Winchester Extreme |

85 |

3160 |

3261 |

1884 |

2006 |

|

2 |

Copper |

Hornady GMX |

80 |

3252 |

3425 |

1878 |

2083 |

|

3 |

Copper |

Fox |

80 |

3240 |

3320 |

1864 |

1958 |

|

4 |

Copper |

Sako Powerhead 2 |

80 |

2889 |

2920 |

1482 |

1514 |

|

5 |

Copper |

Federal Power Shok |

85 |

3120 |

3200 |

1876 |

1933 |

|

6 |

Copper |

Winchester / Nosler ** E-tip |

90 |

3051 |

3050 |

1860 |

1859 |

|

7 |

Lead |

Norma Small Game |

100SP |

2960 |

2986 |

1945 |

1980 |

|

8 |

Lead |

Federal Power Shok |

80SP |

3215 |

3330 |

1835 |

1970 |

|

9 |

Lead |

Sako Gamehead |

100SP |

2964 |

2950 |

1950 |

1958 |

|

10 |

Copper |

Federal Premium |

85 |

3021 |

3200 |

1722 |

1933 |

** Replicated factory load by Precision Rifle Services.

Table 1 confirms that factory values for velocity and muzzle energy figures were higher than those measured using the test rifle used for this project. Eight of the cartridges tested achieved velocities and muzzle energy figures that exceeded the present criteria required in the legislation for shooting the larger deer species (Red, Sika and Fallow) in Scotland. Two fell short of the current muzzle energy requirement of 1750ft/lbs; the Sako Powerhead 2 and Federal Premium (samples 4 and 10).

To note; the velocity of these two cartridges was still sufficient to cause bullet expansion and the production of an effective wound profile at 100m when used in the test rifle.

The velocity and muzzle energy figures produced by 80gr lead based Federal Power Shok (sample number 8) were equivalent to the all of the copper bullets tested. The lead based 100gr cartridges (samples 7 to 9) did produce higher muzzle energy values than all the copper bullets, but this was to be expected as they were 10-20gr heavier.

Bullets (or residual larger sections) were recovered from the bullet catcher after being fired through ballistic gel and soap (see Figure 2 showing bullets 1 to 7). All lead-based bullets were significantly fragmented but some larger sections were recovered. All copper-based bullets remained mostly intact and were recovered. The only exception was the Fox copper bullets where the petals fragmented and were found some distance from the permanent cavity.

First row L-R:

- Winchester extreme 85gr – Sample 1

- PRS replica Winchester/Nosler E-Tip 90gr – Sample 6

- Fox 80gr – Sample 3

- Federal Power Shok 85gr – Sample 5

Second row L-R:

- Hornady GMX 80gr – Sample 2

- Sako Powerhead 2 80gr – Sample 4

- Federal premium copper 85gr – Sample 10

The weight of the pre fired bullets, and those recovered from soap and gel, are shown in table 2 below. In all cases the copper bullets retained a very significant amount of their original weight with the exception of the Fox bullet as discussed above. The residual weight of the lead bullets, as expected, was significantly lower with the increased loss as a result of major fragmentation of the bullets within the soap and gel. No residual fragments were obtained from the Sako lead (sample 9) in the ballistic gel.

Table 2

|

Sample number |

Manufacturer |

Bullet weight (gr) |

Retained weight Soap (gr) |

Retained weight Gel (gr) |

|---|---|---|---|---|

|

1 |

Winchester Extreme |

85 |

84 |

83.9 |

|

2 |

Hornady GMX |

80 |

78.6 |

79.3 |

|

3 |

Fox |

80 |

53.5 |

53.5 |

|

4 |

Sako Powerhead |

80 |

79.9 |

80 |

|

5 |

Federal Power Shok |

85 |

73.7 |

75.8 |

|

6 |

Winchester / Nosler E-Tip ** |

90 |

89.3 |

88.9 |

|

7 |

Norma Small Game |

100 |

68 |

49.3 |

|

8 |

Federal Power Shok |

80 |

30.6 |

47.6 |

|

9 |

Sako Gamehead |

100 |

None found |

38 |

|

10 |

Federal Premium Copper |

85 |

85 |

85 |

** replicated factory load by Precision Rifle Services

Comparison of permanent wound cavity volumes between non-lead and lead based cartridges

After firing all the copper and lead based cartridges into the ballistic soap, dental stone cement was poured into the cavity which was created by the passage of each bullet within the soap block. This void represented the permanent wound cavity and correlates with the length and diameter, and hence shape, of the tissue damage which would occur when the bullet travels through the thoracic cavity of a deer.

There is broad conformity across both the non-lead and lead bullet types with profiles up to ~300mm long and ~50mm wide with a tear drop shape. Variations occur in terms of the shape, and therefore internal volume, of the wound profile.

Some of the copper bullets show penetration into the soap of around ~30mm before bullet expansion commences, whilst the lead equivalents tend to expand more quickly within the first ~10mm after making contact with the soap. Based on the calibration of ballistic soap and replication of animal tissue, these figures can be translated into what would typically be observed when bullets strike the hair, skin and tissues of a deer’s thoracic cavity.

Table 3

|

Sample number |

Manufacturer |

Bullet weight |

Water displacement volume (ml) |

|---|---|---|---|

|

1 |

Winchester Extreme |

85gr |

183 |

|

2 |

Hornady GMX |

80gr |

214 |

|

3 |

Fox |

80gr |

270 |

|

4 |

Sako Powerhead 2 |

80gr |

200 |

|

5 |

Federal Power Shok |

85gr |

194 |

|

6 |

Reloaded E-Tip |

90gr |

272 |

|

7 |

Norma Small game |

100gr |

280 |

|

8 |

Federal Power shok |

80gr |

214 |

|

9 |

Sako Gamehead |

100gr |

260 |

|

10 |

Federal Premium |

85gr |

168 |

From table 3 it can be seen there was considerable variation in the permanent wound cavity volumes both within the copper bullet group and the lead based bullet group. The copper bullets which generated the largest wound cavity volumes were Fox and the replicated Winchester / Nosler E-Tip, while in the lead group the Norma Small Game and Sako Game Head gave similar values.

In the latter case the bullets were 100 gr while the copper bullets were 80 and 90 gr respectively. Three copper bullets gave values of less than 200ml; namely Winchester Extreme, Federal Premium and Federal Power Shok.

The remaining copper and lead bullets gave values in excess of 200 ml. Federal Premium gave the smallest volume of 168 ml.

Comparison of the effectiveness of permanent cavity volumes to vital tissues in red deer thoracic sections

In this section scaled images of the permanent cavity wound casts were overlaid onto scaled rib section images of the Red deer thorax. It is important to note that in addition to the permanent cavity, a temporary cavity is created as the bullet passes through the thorax. This is created by the release of energy radiating out from the bullets pathway and causes significant stretching and tearing of tissues. Although the tissues have some elasticity and rebound after the bullet has passed through, the damage to those tissues remains. In addition, there is damage created by a “shock” wave which travels through fluid blood vessels in particular and this can cause damage to tissue further away from the main wound channel. The thorax in addition is a sealed unit and during inspiration (breathing in) expansion of the lungs using intercostal muscle and the diaphragm, creates negative pressure so forcing air down the trachea and into the lung airways. As the bullet enters the thorax, this sealed cavity is damaged preventing generation of negative pressure in the lungs which are now unable to fill with air. This means the blood is deprived of oxygen which has a very rapid impact on the brain leading to unconsciousness.

Lead bullets additionally fragment, and these fragments radiate outwards from the permanent wound cavity causing laceration and damage often some distance to the original bullet entry. This can be seen when looking at the samples 7, 8 and 9. Fragmentation does not normally occur with copper bullets although in this sample 3, the Fox bullet, did fragment.

Consideration must therefore take into account not only the effects of the permanent cavity, but also the damage caused by the temporary cavity, loss of thoracic seal, fragmentation and shock wave effects.

Copper Bullets

Sample 1 – Winchester Extreme 85gr

Six cross section diagrams of red deer thorax with black lines showing divisions across the thorax to represent the three outcomes below:

One of three outcomes was recorded for each bullet at each rib space and within the three sections at each rib space.

Fatal. Rapidly fatal outcome.

Wounded. May have a fatal outcome but wounding also possible.

Non-fatal. Non-fatal outcome causing wounding and deer moving away.

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Lung, oesophagus, trachea. |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava and lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Lung, oesophagus, trachea |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Lung, oesophagus, trachea |

|

Rib space 4/5 - Middle |

Fatal |

Heart and aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava and lung |

|

Rib space 7 - Ventral |

Fatal |

Heart and lung |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Non-fatal |

Rumen, tip of liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

Lead Bullets

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

|

Rib space |

Outcome |

Tissues affected |

|---|---|---|

|

Rib space 2 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 2 - Middle |

Fatal |

Brachial artery, vena cava, lung |

|

Rib space 2 - Ventral |

Wounded |

Lung |

|

Rib space 3 -Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 3 - Middle |

Fatal |

Brachial artery, vena cava |

|

Rib space 3 - Ventral |

Fatal |

Heart |

|

Rib space 4/5 - Dorsal |

Wounded |

Oesophagus, trachea, lung |

|

Rib space 4/5 - Middle |

Fatal |

Heart, aorta |

|

Rib space 4/5 - Ventral |

Fatal |

Heart |

|

Rib space 6 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 6 - Middle |

Fatal |

Heart |

|

Rib space 6 - Ventral |

Fatal |

Heart |

|

Rib space 7 - Dorsal |

Fatal |

Aorta, pulmonary veins, lung |

|

Rib space 7 - Middle |

Fatal |

Vena cava, lung |

|

Rib space 7 - Ventral |

Fatal |

Heart |

|

Rib space 9 - Dorsal |

Fatal |

Aorta, liver, lung |

|

Rib space 9 - Middle |

Wounded |

Rumen and liver |

|

Rib space 9 - Ventral |

Non-fatal |

Rumen |

Discussion

Of the three non-lead 80 gr .243w cartridges tested (Hornady GMX, Fox and Sako Powerhead 2), all but the Sako cartridge met and exceeded the current minimum requirements regarding velocity (2,450 fps) and energy (1,750 ft/lb) contained in The Deer (Firearms etc.) (Scotland) Order 1985.

Of the three non-lead 85 gr .243w cartridges tested (Winchester Extreme, Federal Power Shok and Federal Premium), all but the Federal Premium met and exceeded the current minimum requirements regarding velocity (2,450 fps) and energy (1,750 ft/lb) contained in The Deer (Firearms etc.) (Scotland) Order 1985. The Federal Premium had a sub 1750 ft/lb output of 1722ft/lb.

The replicated non-lead 90 gr Winchester Nosler e-tip, met and exceeded the current minimum requirements regarding velocity (2,450 fps) and energy (1,750 ft/lb) contained in The Deer (Firearms etc.) (Scotland) Order 1985.

All the non-lead bullets tested, with the exception of the Fox 80 gr, expanded to approximately twice their diameter. The Fox bullet broke up (see Table 2 & Figure 2) and the recovered bullet weight was reduced from 80gr to 53.5gr.

In considering the volume of water displaced by the cast of the permanent wound profile as a proxy for wound shape and size, the three non-lead 80gr bullets gave an average wound volume of 228ml. The three 85gr bullets gave an average wound volume of 182ml and the 90 gr Winchester/Nosler at 272ml.

The three lead bullets tested gave average wound volumes of 251ml.

Excluding i) the lead 80 gr Federal Power-Shok from the test as not meeting the current legal minimum bullet weight (for the larger deer species) in The Deer (Firearms etc.) (Scotland) Order 1985, and ii) excluding the Sako Powerhead 2 as not achieving the minimum muzzle energy criteria The Deer (Firearms etc.) (Scotland) Order 1985, gives the following results:

The average permanent wound volume for non-lead .243w ammunition, with bullet weights of 80gr to 90gr, was 216 ml whilst the100 gr lead bullets resulted in an average wound profile volume of 270ml.

To note the non-lead Winchester/ Nosler 90gr bullet exceeded the average performance of the current legal 100gr lead bullets resulting in a permanent wound volume of 272ml compared to 270ml.

It should also be noted that due to the breakup of the Fox bullet, in both the ballistic gel and soap, gave a somewhat distorted outcome to the non-lead bullet permanent wound volume measurements. This bullet did not appear to hold together and expand in the same fashion to comparable non-lead bullet weights. Its makeup and construction result in a larger frontal area which on expansion still created the desired wound profile.

Conclusions

To use non lead bullets in the .243w cartridge, the weight component of the tripartite criteria of bullet weight, velocity and muzzle energy as prescribed by The Deer (Firearms etc.) (Scotland) Order 1985. must be compromised. The question is will this compromise the culling efficiency and have a detrimental effect on deer welfare? It would appear that all 85gr and upwards bullet weights generate in excess of 1700ft/lb in a typical deer stalking rifle.

Based on the recorded velocities and muzzle energies of <100gr non-lead bullets in currently commercially available factory .243w cartridges, the observed permanent wound casts, and using the recorded wound volumes as an indicator of the permanent wound size and shape, confirm that there would be no detrimental effect on deer welfare. Where bullet placement is in line WDBPG, and where velocity and muzzle energy criteria are still met, bullet weights from 80 to <100gr can still deliver the required damage to the vascular system within the thoracic cavity.

Although not investigated in this report, the group is aware that advances in firearms have developed smaller calibre bullets in .22 centrefire configuration which are capable of delivering ballistic performance that may satisfy the current legislation. They may conform in terms of velocity and muzzle energy however the bullet weight is less than 100gr. Therefore there could be unintended consequences if the bullet weight component of current legislation is reduced as the only amendment to The Deer (Firearms etc.) (Scotland) Order 1985.

Deer legislation covering the use of firearms is not uniform across the UK. Care must be taken by visiting deer stalkers to comply with different legislation when stalking deer in Scotland, England, Wales and Northern Ireland.

England and Wales legislation stipulates for all deer a minimum of .240 calibre and minimum muzzle energy of 1,700ft/lb. Northern Ireland requires a rifle of calibre not less than .236, a minimum bullet weight of 100gr and a minimum muzzle energy of 1700ft/lb.

Recommendations

Consideration could be given to amending The Deer (Firearms etc.) (Scotland) Order 1985 and creation of a new order with an addition of a minimum calibre stipulation of .240 along with a reduction in bullet weight from 100gr to 80gr for the culling of all species of deer.

Alternately the bullet weight could be removed from the tripartite arrangement and the legislation could simply concentrate on a minimum calibre of .240 and minimum muzzle energy of 1700ft/lbs - as per legislation in England and Wales.

The stipulation of .240 minimum calibre categorically removes any opportunity for .22 centrefire calibres to be used in controlling Scotland’s larger deer species in the future.